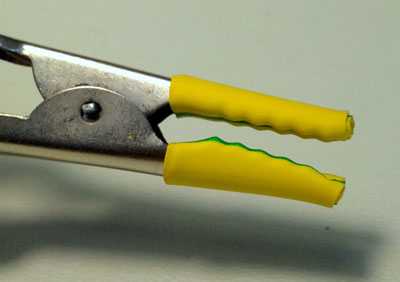

When soldering electronic parts together, one hand holds the soldering iron and one hand feeds the solder, leaving no hands to hold the parts being soldered. There's a common tool nicknamed a third hand which helps here. The tool has one or two (or three) adjustable alligator clips to hold parts and usually has a magnifying glass to help see the work.

Mine was always a little difficult to use. The clips would fall out of their holders, and the teeth on the clips tended to bite through insulation on wires. I lived with this for years without thinking much about it, but finally fixed it. It took 10 minutes. I should have fixed it years ago.

First, following this advice from Robot Room, I strengthened the base of the clips so they wouldn't fall out. The problem is that there's a screw which clamps down on a flimsy, hollow tube and can easily crush the tube. Solution: fill the hollow tube with metal so it can't be crushed. The article suggested using a brass rod, but I didn't have that so instead I found a bolt which fit, cut it to the right length, and screwed it in.

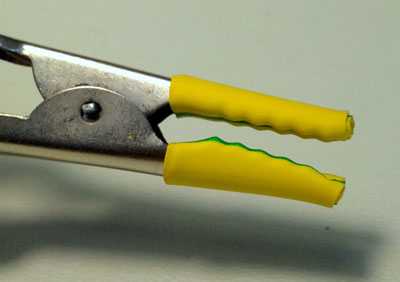

Second, I put two layers of heatshrink over the teeth so they aren't as sharp. Should help protect wires.

These were both easy fixes. If you have one of these third hand tools, you should take 10 minutes and fix it up!

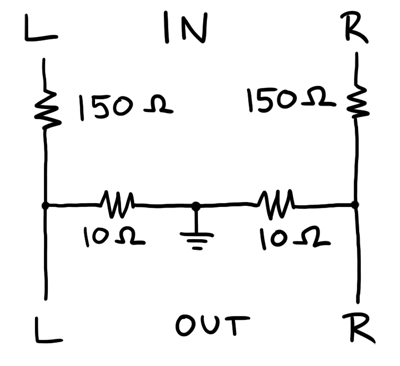

My headphones are too loud. I have in-ear headphones which seal out outside noise and are quite sensitive. I have to keep the volume at its lowest setting, almost off, for comfortable listening. This has two drawbacks: it is painfully loud if the volume ends up at its max setting, and there's usually a hiss coming from my phone or laptop which competes with the music at the lowest volume setting.

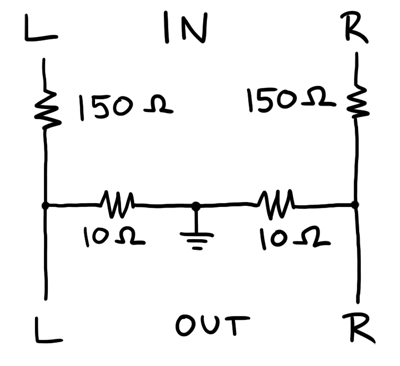

To fix this, I made a short headphone cable which reduces the volume. This is similar to the headphones which have a volume knob or slider built into the cable, except that it only has one setting: quiet. The circuit is two simple voltage dividers, one for the left channel and one for the right channel. I found the resistor values through trial-and-error on a breadboard, just trying different values until I found some that gave the ideal volume reduction. The circuit is tiny enough to fit inside the headphone jack and it works well. I can now comfortably use the entire volume range when listening to music, and at the higher volume settings the hiss is drowned out by the music so I can't hear it any longer.

BEEP BEEP BEEP BEEP…

I hate waking up to an alarm clock. Especially on cold, dark winter mornings. My wife and I want to bike to work around dawn (so we can leave work and ride home before dark) which means we have to get up while it is still dark outside. This is painful with a regular alarm, but we’ve been experimenting with a prototype sunrise alarm built with an Arudino.

I’ve noticed that in the spring, when sunrise is getting earlier, it becomes easier to wake up before the alarm goes off. This feels wonderful: instead of feeling groggy, I feel rested and sometimes even energetic. In the fall, though, the trend reverses and it gets harder to wake up as it gets darker each morning. The sunrise alarm counteracts this trend by simulating an early sunrise, making sure the room is bright when it is time to wake up. This prompts the body to wake up naturally, rather than shocking it awake with loud noises.

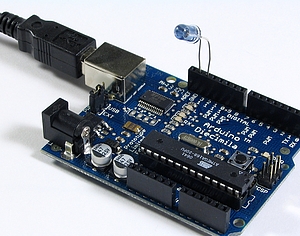

The hardware for our prototype alarm is simple: I have a Lutron Maestro wireless light dimmer, and the Arudino is controlling it with a single IR LED. (You can read more about how to use the Arudino as a remote control in this post). The nice thing about controlling the dimmer wirelessly is that everything is 5 volts, and I don’t have to worry about 120 volt shocks.

The software uses the remote control signal code described in the earlier post and combines it with the example from the Arduino DateTime library. The DateTime example has code for setting the clock on the Arudino over USB. I extended the code to set the current time and also set the time for the alarm to go off. The Arduino waits for the alarm time to arrive, then starts sending commands to the light dimmer to slowly turn on the lights. Right now I have it turn them on over the course of 20 minutes.

At the moment this is just a prototype. I’ve been pretty happy with it so far, so at some point I’ll probably rebuild it using a bare AVR chip (so that I can use the Arudino for other projects). Here are some of the things I’ve noticed so far from using it:

At the moment this is just a prototype. I’ve been pretty happy with it so far, so at some point I’ll probably rebuild it using a bare AVR chip (so that I can use the Arudino for other projects). Here are some of the things I’ve noticed so far from using it:

- Using the regular lights in our room guarantees that it is bright enough to wake us up. It is a little too bright, actually. I might put lower-wattage bulbs in.

- I originally had it turn the lights on over 15 minutes. However, that felt too sudden. I kept waking up when it was already pretty bright. I slowed it down to take 20 minutes total; it ramps up to half brightness over the first 15 minutes then up to full brightness in the last 5 minutes. This seems to be more gentle. It might be worth experimenting with even longer periods of time, like 30 minutes.

- The Arudino Diecimila resets when it is connected or disconnected from USB, losing the time. However, if you just yank the USB cable it won’t reset. This is nice because otherwise I’d have to leave my laptop turned on all night just so the Arudino wouldn’t lose the time. Leave the IDE running and connected to the Arduino, then unplug the cable without disconnecting in software. You’ll need to have the Arduino powered from a dedicated power supply so there’s still power after the USB is unplugged.

- I originally had it run once and then stop, but that meant I had to set the alarm again every day which was a hassle. I changed it to automatically move the alarm time forward 24 hours, which is much more convenient (but also risky…if I forget and leave it running when we go on a trip, it will turn the lights on and leave them on).

- Bugs in this type of device are annoying. If you make a coding mistake, it might turn the lights on in the middle of the night, or turn them on and leave them on all day. It might also fail to work at all, letting you oversleep.

We’re still setting our regular alarm to go off a few minutes after the lights reach full brightness, just in case we don’t wake up. (I may add a speaker to the finished alarm to consolidate this). Most days I’m already awake or just lightly dozing when it goes the regular alarm goes off, which is good. It feels much more civilized than getting dragged out of bed in the dark by that awful beeping.

It is really easy to build a universal remote using an Arduino. With just an infrared LED, it can impersonate remotes for your TV, fans, lights, etc. and can let you easily incorporate these into your electronics projects. You won’t even have to solder anything or void any warranties.

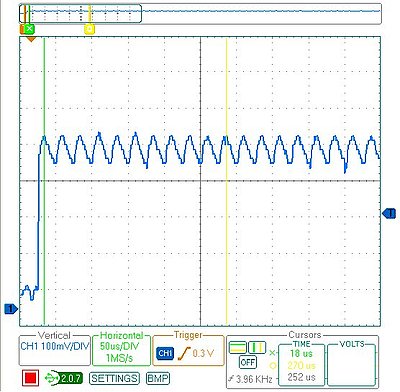

For a project I’m working on, I need to emulate the remote for a Lutron Maestro light dimmer. It uses a modulated IR signal, which is a common way for remotes to communicate and is easy to generate with an Arduino. The basic scheme is simple: each command is sent as a series of pulses representing bits, which can be either 1 or 0. To send a 1, you rapidly blink the LED on and off at 38 kHz, and for 0 you leave the LED off. (The 38 kHz modulation makes the signal more resistant to interference from other light sources).

Decoding the Signal

To decode what the remote was sending, I used an oscilloscope and a small photodiode. The photodiode generates a small amount of voltage when light hits it, and responds to changes in light level quickly enough that the oscilloscope can draw a really nice plot of the signal. I have a Parallax USB oscilloscope, which is perfect for showing the command pulses and is just fast enough to find the modulation frequency. As an aside, I’m really happy with the Parallax oscilloscope for projects like this. It is simple to use and I love being able to save images to share with people.

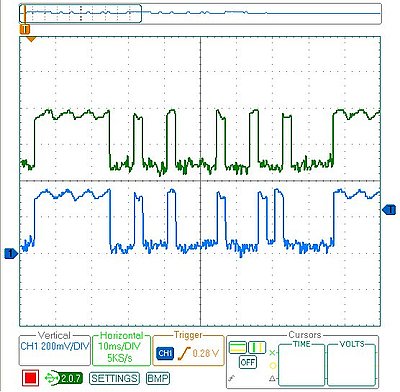

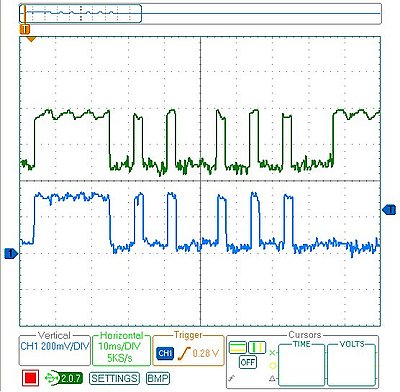

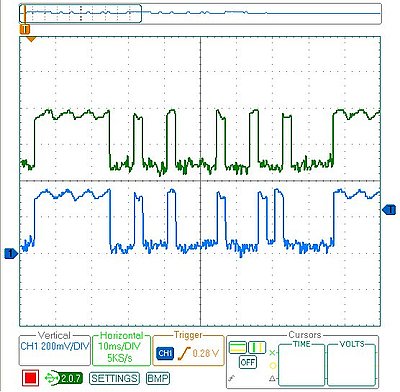

Here’s what two of the commands from the dimmer remote look like. The top signal is the “fade lights up” command, and the bottom one is “fade lights down”:

I captured several different commands, then measured the length of all the pulses. Looking at all the commands, a couple patterns are obvious:

- The entire command takes 82.8 ms (after which it immediately repeats, presumably because I held the button on the remote down a little too long).

- The lengths of the on/off pulses are all multiples of 2.3 milliseconds (which means that the entire 82.8 ms command represents 36 bits of data).

- The last four bits are always 0, so really each command is four bytes long, followed by four 0 bits

The particular remote I’m emulating has five commands, and once they are decoded they look like this:

fade up = [255, 136, 130, 34]

fade down = [255, 136, 130, 20]

full on = [255, 136, 132, 184]

full off = [255, 136, 189, 18]

memory recall = [255, 136, 132, 183]

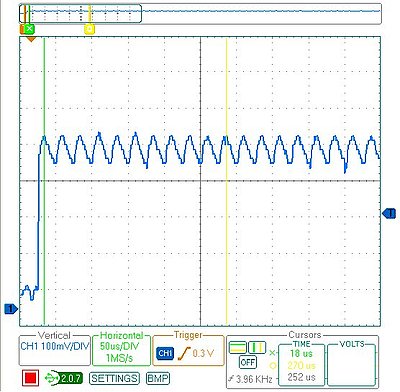

The one other missing piece of information is the modulation frequency which can be measured by zooming in on any of the pulses. This remote uses a frequency of 39.68 kHz. (In the plot below, it says the frequency is 3.96 kHz because I included 10 pulses in the measurement to increase accuracy)

Programming the Arduino

Using an Arduino makes the circuit really simple. I put an IR LED between pin 13 and ground. Since pin 13 has an internal resistor, that’s all that’s required. The code is also pretty straightforward:

/* Control a Lutron Maestro light dimmer */

#define BIT_IS_SET(i, bits) (1 << i & bits)

// LED connected to digital pin 13

const int LED_PIN = 13;

// Width of a pulse, in microseconds

const int PULSE_WIDTH = 2300;

// # of bytes per command

const int COMMAND_LENGTH = 4;

const int UP[] = {255, 136, 130, 34};

const int DOWN[] = {255, 136, 130, 20};

const int ON[] = {255, 136, 132, 184};

const int OFF[] = {255, 136, 189, 18};

const int RECALL[] = {255, 136, 132, 183};

void setup()

{

pinMode(LED_PIN, OUTPUT);

}

/* Modulate pin at 39 kHz for give number of microseconds */

void on(int pin, int time) {

static const int period = 25;

// found wait_time by measuring with oscilloscope

static const int wait_time = 9;

for (time = time/period; time > 0; time--) {

digitalWrite(pin, HIGH);

delayMicroseconds(wait_time);

digitalWrite(pin, LOW);

delayMicroseconds(wait_time);

}

}

/* Leave pin off for time (given in microseconds) */

void off(int pin, int time) {

digitalWrite(pin, LOW);

delayMicroseconds(time);

}

/* Send a byte over the IR LED */

void send_byte(int bits) {

for (int i = 7; i >= 0; i--)

{

if (BIT_IS_SET(i, bits)) {

on(LED_PIN, PULSE_WIDTH);

} else {

off(LED_PIN, PULSE_WIDTH);

}

}

}

/* Send a full command */

void command(const int bytes[]) {

for (int i = 0; i < COMMAND_LENGTH; i++) {

send_byte(bytes[i]);

}

off(LED_PIN, 4 * PULSE_WIDTH);

}

void loop()

{

command(UP);

delay(1000);

command(DOWN);

delay(1000);

}

Checking the Arduino with the Oscilloscope

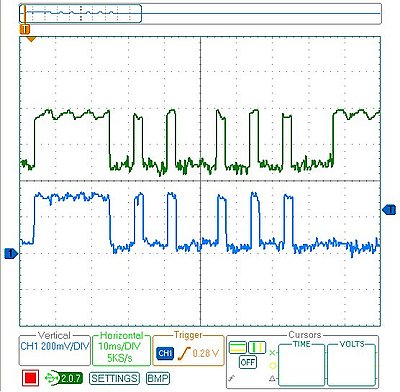

After programming the Arduino, I used the oscilloscope to check the output of the Arduino vs. the original remote. On my first attempt, the wait_time in on() was too long, so the command was stretched out. I hadn’t accounted for the fact that the digitalWrite() calls would consume some time, so I just decreased wait_time until the length of the overall command was correct. As you can see, the final synthesized command overlaps exactly with the authentic one. The green signal on top is from the remote, and the blue signal on the bottom is the arduino:

Final Test

Once everything was ready to go, it was time for the last test: I tried using the Arduino in place of the remote and it worked! It was able to control the light dimmer flawlessly. This lets me finish my project, plus now that I have all the code written it should be easy to adapt to other remote control devices.

Trying to get started with AVR microcontrollers, but bewildered by the sheer number of options? So was I, a short time ago. It took several weeks of reading before I felt like I understood how everything fit together. I’ll write it down and hopefully save you a couple of weeks.

(A short aside: if the rest of the post makes it clear that AVRs are too much for you, consider getting an Arduino. They have an AVR chip in them, but are easier to use.)

First, let’s look at what a complete setup looks like:

- AVR chip

- The rest of the circuit

- Hardware programmer

- Software to run the programmer

- Compiler toolchain for your language of choice (assembler or C)

AVR Chip

There’s a huge spectrum of options in the different AVR chips. Don’t worry though, they are all fairly compatible in terms of learning how to program them. They differ in how much memory they have, how many fancy peripherals (like ADCs, UARTs, PWM generators) they contain, what package they come in, and of course how much they cost. You just need to pick the chip that has the right combination of features for your application. If you just want to play around, I’d suggest getting one of the fancier AVR chips, like an ATmega168. Then you’ll have plenty of features for whatever you want to try.

Atmel has a nice product grid that lets you quickly compare the different chips.

If you really need a specific feature for your project, be sure to double-check the datasheet and make sure there isn’t some little gotcha waiting there. Lots of features share pins or internal hardware, or have unexpected restrictions, so you need to understand the datasheet. For example, the timer and PWM generator may share the same counter internally, or one of the output pins might be shared with a pin used by the programmer.

Here’s a suggestion for saving a lot of time: Start with an over-powered chip. Sure, those 8-pin chips are cute, but they don’t have very many peripherals or memory. When you realize you need a 2nd UART which you don’t have, or that you really need 256K more memory, you’ll be sad. Instead, start with one of the fancier chips and use the extra hardware to get your project done sooner. Then, if you still want it to run on a smaller/cheaper chip, you can start optimizing your software and writing bit-banging routines to replace the peripherals.

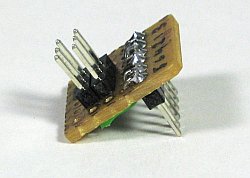

ISP Header

The only AVR-specific part of your circuit is an ISP programming header. This is where you plug in the programmer to download your software onto the AVR chip. It is really easy to build a small ISP adapter that plugs into your breadboard. I explained how I built one here. I suppose you could also just jam wires into your breadboard, but that would be messy.

You’ll want a solderless breadboard to prototype your circuit in (later, once it is perfect, you can move it to perfboard or a PCB, but until the circuit it perfect you’ll be changing it a lot so you want to start on the breadboard). You need some kind of power supply. I built one of these on the corner of my breadboard. You could also use batteries, or the +5 line from a USB connection.

Programmer (Hardware)

This piece of hardware is how you get your programs onto the AVR chip. There are a lot of options, but many of them are outdated. What you want is a USB programmer that does In-System Programming (ISP). Examples:

Whatever one you get, you need to be sure that it will work with your programming software.

Programming software

You need software to control the programmer (confusingly, this software is also occasionally called a programmer). There are a bunch of different pieces of software to do this but the most common 2 seem to be AVR Studio and avrdude. Both are free. Avrdude supports a ridiculous number of different programmers, but you probably want to double-check and make sure the one you are about to buy is supported.

Compiler toolchain for your language of choice (assembler or C)

You can program the AVR in either assembler or C. Since we want to pick the easy road, that narrows it down to C. As far as I can tell, all the different IDEs and tools end up using avr-gcc under the covers. So, you need to get the avr-gcc toolchain:

- Windows: WinAVR

- OSX: OSX-AVR

- Linux: For Ubuntu, you can get slightly outdated versions from apt: apt-get install binutils-avr gcc-avr avr-libc

Where to Go From Here

Ok, you’ve collected all your hardware & software. Now you need to put it all together. Fortunately, there’s already a lot of great information out there on how to get started with blinking some LEDs. Here are some links to get you going:

SparkFun’s tutorials

Piconomic Design’s tutorials

Using an AVR in a breadboard can be a bit ugly because programmers like the AVRISP mkII and the USBtinyISP can’t easily be plugged into a breadboard.

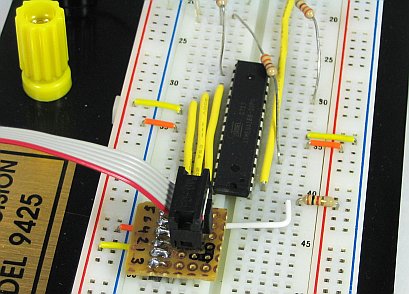

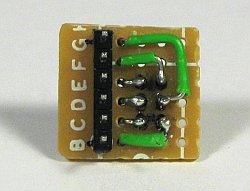

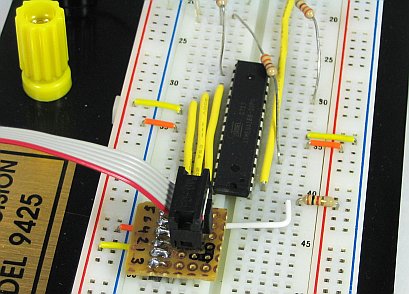

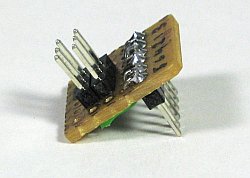

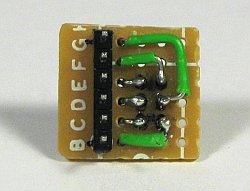

You can simply stick wires in the programmer’s jack and plug them into a breadboard (like they do here) but if you want something a little cleaner you can solder up a simple header board like this:

You just need a small piece of perfboard, a 2×3 pin header block, a 6-pin header row, and a little bit of wire. I found it was easier to route the wires if I didn’t bother trying to get the output pins to be sequential. Solder it together and you can leave it in your breadboard, ready for whenever you need to reprogram your microcontroller.

You just need a small piece of perfboard, a 2×3 pin header block, a 6-pin header row, and a little bit of wire. I found it was easier to route the wires if I didn’t bother trying to get the output pins to be sequential. Solder it together and you can leave it in your breadboard, ready for whenever you need to reprogram your microcontroller.

At the moment this is just a prototype. I’ve been pretty happy with it so far, so at some point I’ll probably rebuild it using a bare AVR chip (so that I can use the Arudino for other projects). Here are some of the things I’ve noticed so far from using it:

At the moment this is just a prototype. I’ve been pretty happy with it so far, so at some point I’ll probably rebuild it using a bare AVR chip (so that I can use the Arudino for other projects). Here are some of the things I’ve noticed so far from using it:

You just need a small piece of perfboard, a 2×3 pin header block, a 6-pin header row, and a little bit of wire. I found it was easier to route the wires if I didn’t bother trying to get the output pins to be sequential. Solder it together and you can leave it in your breadboard, ready for whenever you need to reprogram your microcontroller.

You just need a small piece of perfboard, a 2×3 pin header block, a 6-pin header row, and a little bit of wire. I found it was easier to route the wires if I didn’t bother trying to get the output pins to be sequential. Solder it together and you can leave it in your breadboard, ready for whenever you need to reprogram your microcontroller.